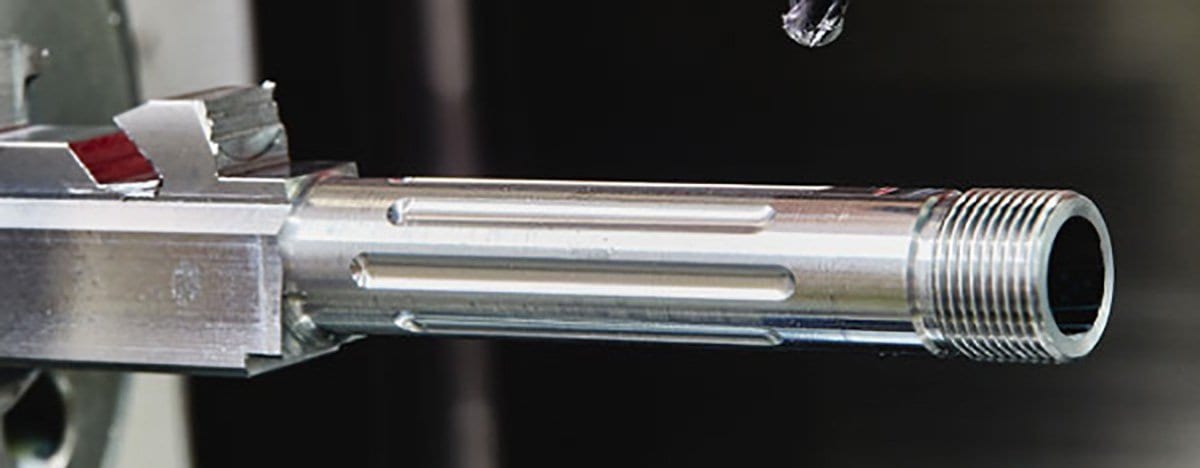

BARRELS

BERGARA MAKES PRECISION BARRELS FOR PRECISION RIFLES

Manufactured in Bergara, Spain, a region known to produce some of the finest guns in the world, Bergara has combined the most technically-advanced barrel manufacturing equipment with an unwavering commitment to quality and value. This superior technology combined with decades of barrel making experience delivers a production barrel that performs like it was custom made.

A HISTORY OF PRECISION

With the most technically-advanced barrel manufacturing techniques, state-of-the-art machinery and an unwavering commitment to quality, Bergara Barrels has become the barrel source of numerous top-tier gun manufacturers in both Europe and the United States. Now, with Bergara Rifles, we are producing a full line of precision rifles, engineered and built to showcase the performance capabilities of our world-class barrels. At Bergara we believe that a precision rifle requires not only the best components, but also an assembly process that is carried out by individuals who are the best of the best at their craft. For this reason, we brought together a team of the world’s most talented and experienced rifle builders – first in the USA for our Custom Series and Premier Series, and now in Spain for our B-14 Series. It all began several years ago when we first began with a small line of custom rifles and one top-notch craftsman, the former Production Chief & Chief Instructor for the United States Marine Corps Precision Weapons Section. As Bergara rapidly grew, he then assembled a hand-picked group of his best PWS alumni, the guys who built the rifles used by US Marines both in combat and competition all over the world. And still today, these Marines form the core of our production team, passing their knowledge and expertise on to every new employee, and thereby bringing their own real world experience and expertise to every Bergara rifle.

STEPS

Step Barrel Straightening

Each Bergara barrel must begin with a straight bar of cylindrical steel. We inspect every bar to ensure it meets a deviation of less than 4/1,000 (or .004) of an inch. Many barrel manufacturers never even evaluate this aspect of a barrel and consequently hinder the barrel’s accuracy potential.

Step Deep Hole Drilling

Once the steel bar is straightened, it moves on to a four spindle deep hole drilling machine where a specialized bit drills a perfect hole through the entire length of the bar.

Step Barrel Honing

Most other barrel manufacturers move from deep hole drilling to reaming, a process that leaves tool marks in the bore. Instead of reaming, Bergara uses three separate honing spindles that utilize diamond tipped bits that polish the interior surface of the barrel to a mirror-like finish that is almost completely free of tool marks. This time-consuming step lends Bergara a level of accuracy on par with barrels costing much more.

Step Button Rifling

A carbide rifling button is drawn through the barrel to produce the rifling grooves at the appropriate twist rate for each caliber. This produces a groove diameter deviation of less than 2/10,000 (or .0002”) of an inch. It’s the same result that many gunsmiths accomplish by hand lapping.

Step Stress Relieving

Finally, a high temperature heating process realigns the steel molecules ensuring that the barrel is free from any stress after the button rifling process.

Contact

For inquiries about OEM barrels, please call or email us here.

877 892 7544

877 892 7544